Wedge Wire Screen Diameter

Screen diameters range from 0.750” to 38” and up in fabricated sections. Your specific tolerance and size requirements will be adhered to and will meet the required industry standards.

Slot Sizes

| U.S. MESH | INCHES | MICRONS | MILLIMETERS |

|---|---|---|---|

| 3 | .265 | 6730 | 6.73 |

| 3.5 | .223 | 5660 | 5.66 |

| 4 | .187 | 4760 | 4.76 |

| 5 | .157 | 4000 | 4.00 |

| 6 | .132 | 3360 | 3.36 |

| 7 | .111 | 2830 | 2.83 |

| 8 | .0937 | 2380 | 2.38 |

| 10 | .0787 | 2000 | 2.00 |

| 12 | .0661 | 1680 | 1.68 |

| 14 | .0555 | 1410 | 1.41 |

| 16 | .0469 | 1190 | 1.19 |

| 18 | .0394 | 1000 | 1.00 |

| 20 | .0331 | 841 | .841 |

| 25 | .0280 | 707 | .707 |

| 30 | .0232 | 595 | .595 |

| 35 | .0197 | 500 | .500 |

| 40 | .0165 | 420 | .420 |

| 45 | .0138 | 354 | .354 |

| 50 | .0117 | 297 | .297 |

| 60 | .0098 | 250 | .250 |

| 70 | .0083 | 210 | .210 |

| 80 | .0070 | 177 | .177 |

| 100 | .0059 | 149 | .149 |

| 120 | .0049 | 125 | .125 |

| 140 | .0041 | 105 | .105 |

| 170 | .0035 | 88 | .088 |

| 200 | .0029 | 74 | .074 |

| 230 | .0024 | 63 | .063 |

| 270 | .0021 | 53 | .053 |

| 325 | .0017 | 44 | .044 |

| 400 | .0015 | 37 | .034 |

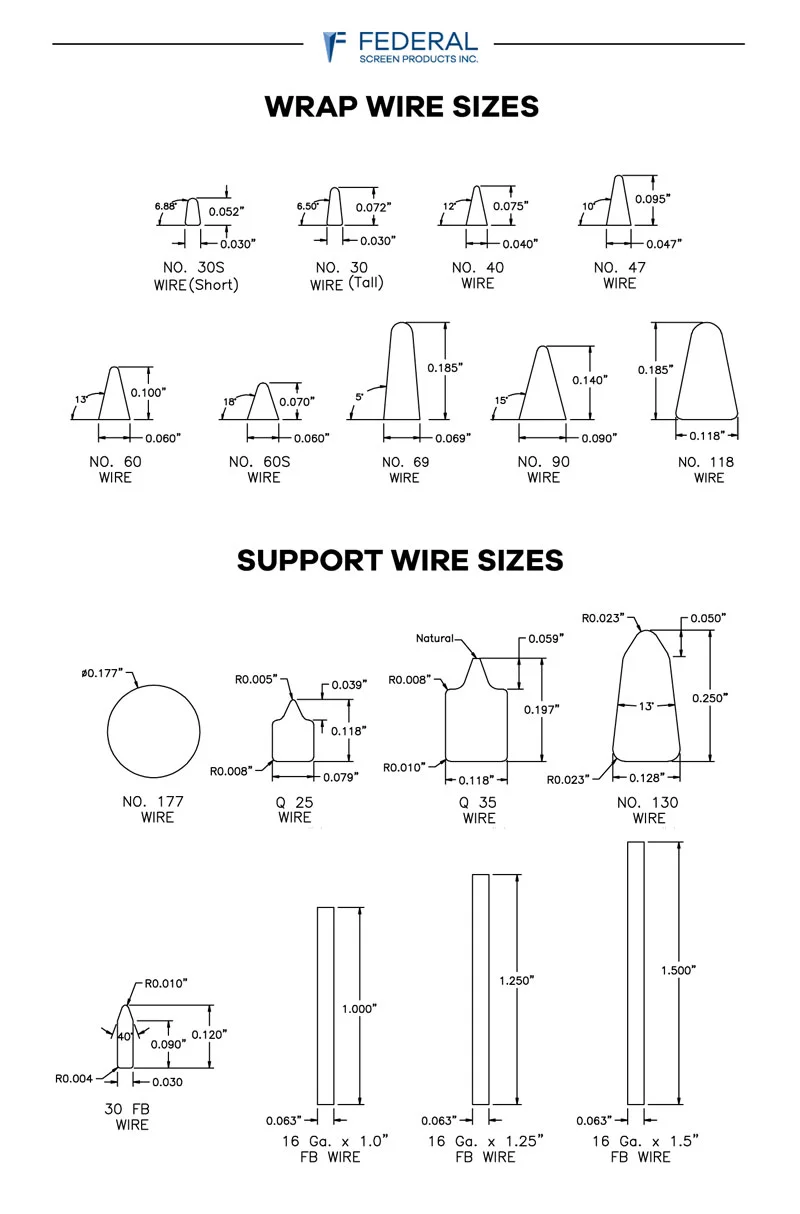

Construction Profiles

We offer numerous combinations of profile wires and support rods. Wedge Wire Screen is created by wrapping a profile wire cylindrically around longitudinally placed support rods. The wide range of apertures between the wires and rods allows us to design a screen according to our customers’ technical or structural specifications.