Frequently Asked Questions

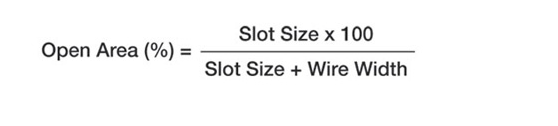

HOW DO YOU FIGURE OUT THE OPEN AREA OF SCREEN?

The open area ratio (OA) of Wedge Wire Screen is calculated using the following formula:

WHAT ARE THE STANDARD TOLERANCES FOR SCREEN?

Tolerance of slot size: +/- .002”

Fabrication: +/- 1/16” (2 PL DEC = 0.020”, 3 PL DEC = 0.010”)

Angles: + /- 1 degree

Specialty tolerance maybe requested, especially on custom machined items.

HOW MUCH DOES IT COST?

All our products are custom manufactured, since there are limitless possible combinations of wire profile, slot size, material choice and length. Depending on the application, the cost per unit varies and must be calculated on a per-job basis.

WHAT IS THE STANDARD SLOT SIZE?

There is no actual standard size. We handle a large range of applications on a day-to-day basis and each requires a very different slot size. Typically, for most applications, the slot size specified by the media supplier should be used.

DOES WEDGE WIRE HAVE LOW PRESSURE LOSS

The high open area of Wedge Wire Screen contributes to a low pressure drop through the screen surface.

HOW IS WEDGE WIRE NON-CLOGGING?

Wedge Wire Screens are fabricated by cylindrically wrapping a continuous V-shaped wire around axial support rods. The uninterrupted slot formed allows for only two points of contact with particles on the screen surface to minimize clogging. This means that the maximum effective flow area and operating efficiency are maintained.

Have a question that isn't listed? Please contact us directly with any questions you may have.

Federal Screen Wedge Wire Screen Manufacturer: Frequently Asked Questions

-

What is the history of Federal Screen?

Federal Screen Products has been a trusted manufacturer of wedge wire screens for over 30 years. Founded with a commitment to precision and innovation, we serve industries including mining, water treatment, food processing, pulp & paper, and petrochemicals. Our continuous growth is driven by a dedication to quality, customer satisfaction, and advanced wedge wire technology.How does Federal Screen commit to sustainability?

We prioritize environmentally responsible manufacturing practices. Federal Screen reduces waste, recycles materials, and uses energy-efficient processes to minimize our environmental footprint. Our wedge wire screens are designed for longevity and performance, supporting sustainable filtration and separation solutions.Where is Federal Screen located, and do you have multiple facilities?

Federal Screen is headquartered in Mississauga, Ontario, Canada. Our central manufacturing facility is equipped with advanced machinery and serves customers globally. While we operate from a single site, our distribution capabilities allow us to efficiently service clients across North America and beyond.What core values and principles guide Federal Screen's operations?

Our operations are driven by precision, quality, customer-centricity, integrity, and innovation. These values ensure we deliver exceptional wedge wire products and develop long-term partnerships with our clients.What sets Federal Screen apart from its competitors in the industry?

Our competitive edge lies in our technical expertise, custom engineering capabilities, high-quality standards, fast turnaround times, and customer-first approach. We also utilize state-of-the-art wedge wire screen manufacturing technology to deliver consistent and reliable performance. -

What are the primary applications of wedge wire screens in various industries?

Wedge wire screens are used in water and wastewater treatment, mining, food processing, pulp and paper, petrochemical, and pharmaceutical industries. Applications include filtration, separation, sizing, and media retention.How do Federal Screen’s wedge wire screens compare in terms of durability and performance?

Our wedge wire screens are manufactured using high-grade stainless steel and precision welding techniques, ensuring exceptional durability, corrosion resistance, and operational efficiency, even in demanding environments.What range of sizes and shapes are available for wedge wire screens?

We offer a wide variety of screen profiles including cylindrical, flat panels, sieve bends, and custom shapes. Slot openings range from 0.025 mm to over 10 mm, tailored to specific filtration requirements.Can wedge wire screens be customized for specific applications?

Yes, we provide fully customized wedge wire screens based on client specifications. This includes custom slot sizes, profiles, dimensions, materials, and configurations.What materials are used in the manufacturing of wedge wire screens?

Primarily, we use stainless steel grades 304, 316, and 316L. Other materials such as duplex stainless steel, Hastelloy, and titanium are available for specialized applications.How do wedge wire screens contribute to efficiency in filtration and separation processes?

Wedge wire screens provide consistent slot openings and precise flow paths, ensuring maximum filtration area, reduced clogging, and efficient separation. Their robust design leads to long service life and minimal maintenance.What maintenance is required for wedge wire screens?

Maintenance is minimal. Periodic cleaning using water, mild chemicals, or ultrasonic cleaning systems is usually sufficient to maintain performance.How does Federal Screen ensure the quality of its wedge wire screens?

Our quality control includes material testing, dimensional inspection, weld integrity testing, and final performance checks to meet ISO and industry-specific standards.Are there any innovative features of Federal Screen’s wedge wire screens that enhance their functionality?

Yes, we offer proprietary welding techniques, optimized slot profiles, and customized reinforcement designs that improve screen strength and performance under high pressure or abrasive conditions.How does Federal Screen handle large orders and specific demands for wedge wire screens?

We have the production capacity and supply chain flexibility to manage large-scale projects and unique technical requirements. Our team collaborates closely with clients to meet delivery timelines and performance expectations.n text goes here -

What advanced manufacturing technologies does Federal Screen use in screen production?

Our facility is equipped with state-of-the-art CNC machinery, water jet cutting systems, and automated welding stations, ensuring precise and repeatable manufacturing.How does Federal Screen incorporate automation and robotics in its manufacturing process?

We use automation and robotic systems to enhance production speed, accuracy, and worker safety. This allows us to maintain consistency across large batches and reduce turnaround times.Can you describe the water jet cutting technology used at Federal Screen?

Our high-pressure water jet cutting system enables intricate cuts and custom shapes without heat distortion. This is crucial for maintaining structural integrity and design precision in wedge wire components.What are the quality control measures in place during the manufacturing process?

Our process includes in-line inspections, automated dimensional checks, material certification, and post-production testing to meet rigorous quality standards.How does Federal Screen ensure precision and consistency in its products?

We rely on CNC-controlled equipment and skilled technicians to ensure tight tolerances, consistent slot openings, and high-performance welds.What role does engineering expertise play in Federal Screen’s manufacturing process?

Our engineering team collaborates with clients to develop custom filtration solutions. They design, prototype, and optimize products to meet performance, regulatory, and durability requirements.How does Federal Screen’s technology contribute to custom solution development?

Our technology enables us to create tailored solutions with complex geometries and performance criteria, ensuring optimal performance for each application.What are the environmental considerations in Federal Screen’s manufacturing technology?

We implement eco-friendly practices including water recycling, minimal waste generation, and energy-efficient equipment to reduce our environmental impact. -

What certifications do Federal Screen products meet?

Federal Screen products meet ISO 9001:2015 certification standards and comply with ASME and ASTM guidelines, ensuring quality and performance.How does Federal Screen ensure compliance with industry-specific regulations?

We maintain detailed documentation, conduct regular audits, and design products to meet industry-specific codes and regulatory requirements.What quality control processes are in place at Federal Screen?

We employ a multi-stage quality control system, from raw material inspection to final product testing. This ensures that each screen meets client and regulatory standards.Can Federal Screen provide material traceability reports for its products?

Yes, full traceability documentation including mill test reports (MTRs) and heat numbers is available upon request.How does Federal Screen manage quality assurance in custom projects?

We assign dedicated project managers and engineers to oversee quality at each stage of custom development, from design approval to final delivery.What steps are taken to ensure product reliability and longevity?

Our screens undergo stress testing, weld integrity analysis, and performance validation to ensure reliability under demanding conditions. -

How can I place an order with Federal Screen?

Orders can be placed by contacting our sales team via phone, email, or through the request form on our website. Our representatives will guide you through the quoting and ordering process.What are the payment terms and methods accepted by Federal Screen?

We accept major credit cards, wire transfers, and purchase orders with approved credit terms. Standard payment terms are net 30 days for approved clients.What shipping options are available, and how are shipping costs calculated?

We offer standard, expedited, and freight shipping options. Shipping costs are based on weight, dimensions, destination, and delivery speed.How long does it typically take to receive an order once placed?

Standard lead times range from 2–4 weeks depending on order complexity. Rush orders can be accommodated upon request.Can Federal Screen accommodate rush orders?

Yes, we prioritize rush orders and adjust production schedules when possible. Additional charges may apply.Does Federal Screen provide order tracking information?

Yes, we provide tracking numbers and carrier details once your order has shipped.What is Federal Screen's policy on order cancellations or modifications?

Order changes or cancellations must be requested within 24 hours of confirmation. Custom orders may not be eligible for cancellation once production begins.How does Federal Screen handle international orders and shipping?

We ship globally and can accommodate international shipping requirements including customs documentation, export compliance, and freight forwarding. -

What warranty options are available for Federal Screen products?

We offer a standard one-year warranty against manufacturing defects. Extended warranty terms may be available based on application and usage.How can customers get technical support for installed products?

Technical support is available via phone, email, or on-site consultation. Our team assists with troubleshooting, installation guidance, and performance optimization.How does Federal Screen handle product returns or exchanges?

Returns are handled on a case-by-case basis. All returns must be pre-authorized and are subject to inspection and restocking fees.What is the process for reporting a problem with a received product?

Please contact our customer service team with your order number and issue description. We will assess and resolve the matter promptly.Can Federal Screen provide technical support for product installation or usage?

Yes, our technical team offers guidance and recommendations for installation and optimal usage.Are there maintenance guidelines available for the upkeep of Federal Screen products?

Yes, we provide cleaning and maintenance guides tailored to the product and application.How can customers get replacement parts for products purchased from Federal Screen?

Replacement parts can be ordered directly through our sales department. We’ll ensure compatibility with your original product. -

What is the process for requesting a custom design from Federal Screen?

Customers can submit their design requirements via our website, email, or by calling our sales team. Our engineers will then review the application and provide design concepts and quotes.What types of customization options are available for Federal Screen products?

Customization includes material selection, slot width, wire profile, screen size, reinforcement style, and special coatings.What is the typical timeline for a custom design project from conception to completion?

Custom projects usually take 3–6 weeks depending on complexity. Design approval, prototyping, and production are coordinated for timely delivery.How are costs determined for custom design services at Federal Screen?

Costs are based on material, design complexity, production time, and any testing or documentation requirements.Can Federal Screen assist in prototyping and testing of custom designs?

Yes, we offer prototyping and testing services to validate performance and refine designs before full-scale production.How does Federal Screen handle intellectual property rights for custom designs?

Client confidentiality and IP protection are a priority. Design rights are discussed and documented before project initiation.