Support Grids

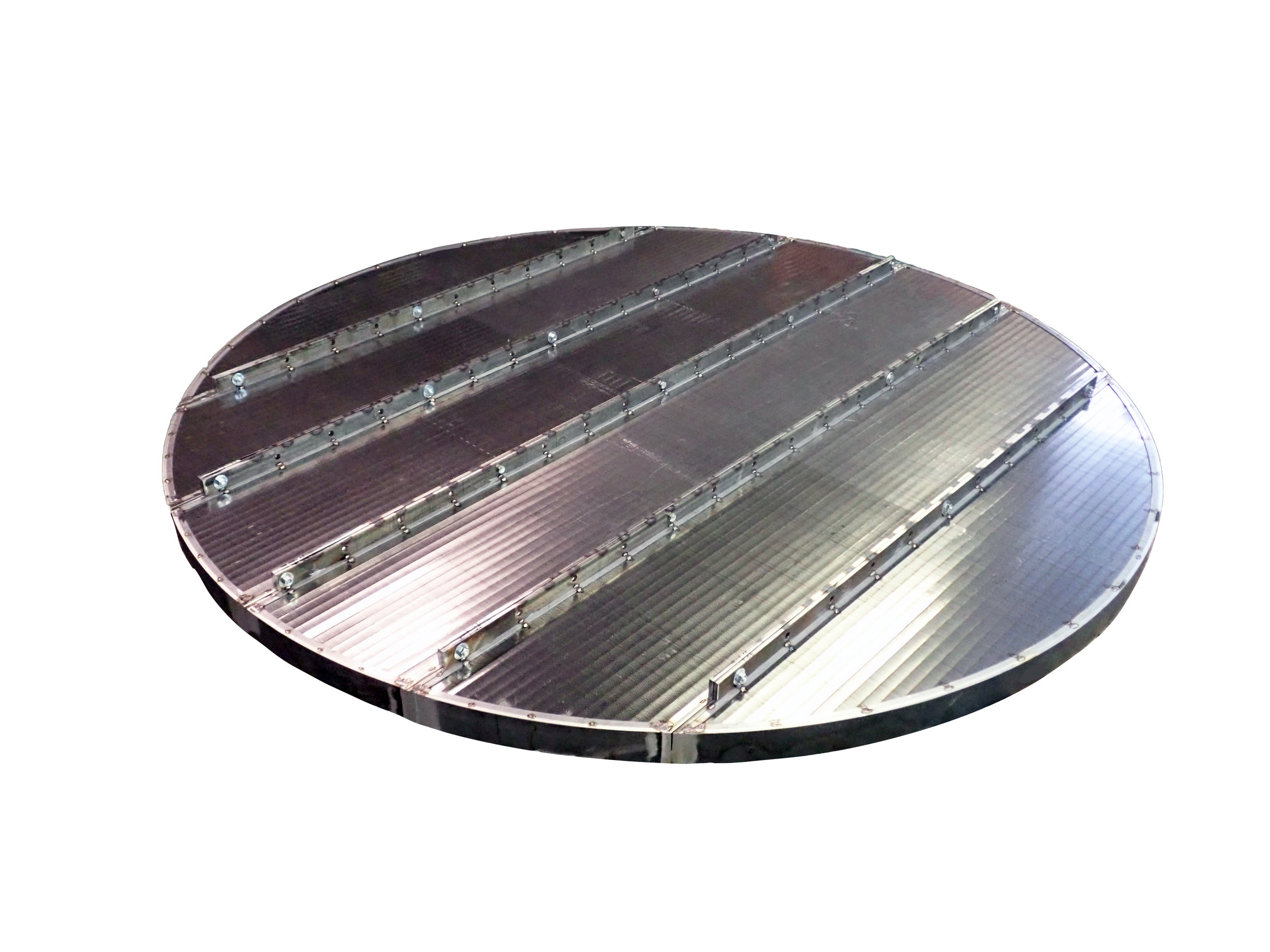

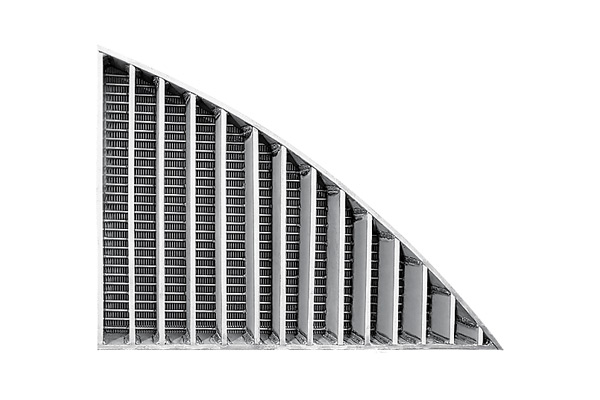

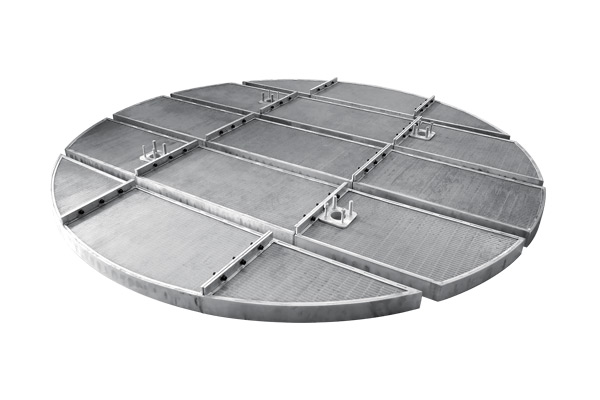

Available in one-piece or sectional design

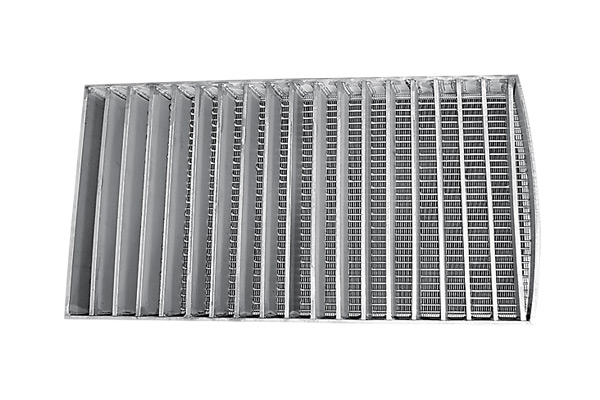

Our support grids are available in a variety of framing options and designs, from one-piece construction to multiple sections. This allows for easy on-site assembly, retrofitting and transporting sections through existing manways. These self-supporting structures have exceptional resistance to collapsing and buckling, even in operations where screens must bear extremely high loads. Media support grids fabricated with Wedge Wire are a good choice when dealing with retaining media in vessels of all types.

Single sectioned

Multiple sectioned

Bolted design

Welded design

304/304L

316/ 316L

321

410S

Hastelloy C-276

Duplex

Super Duplex

Alloy B3

Monel 400

Alloy 20

Additional support structure can be offered depending of system requirements.

Better in every way

Compared to wire mesh and perforated metal, Wedge Wire’s continuous slots have more open area. Their consistent slots are more durable and virtually non-clogging to reduce media abrasion.

Designed and manufactured

Our grids have great design flexibility and are constructed in a wide variety of shapes and sizes and from a variety of corrosion-resistant alloys. Specific processes and vessel requirements can be accommodated. For available corrosion-resistant materials, see material list.

Benefits of our support grids include:

Continuous-slot design provides an increased open area

The continuous slot formed by V-shaped surface wires ensures a two-point contact between the particles and the slot to minimize clogging

Wide range of profile wires are available to suit most applications

High-precision slot sizes are available to meet your requirements

V-shaped surface wires allow for easy cleaning

Very low pressure drop

Additional supports are utilized to accommodate extreme load conditions

Low maintenance

SPECIFICATIONS

PRODUCT QUOTE

Support Grids

Federal Screen’s support grids are available in a variety of framing options and designs, from one-piece construction to multiple sections.

Can't find the support grid you need?

We specialize in custom manufacturing. Our sales, engineering and production teams have the experience to manufacture what you need to the highest degree of excellence. Keeping all work in house allows us to offer accuracy and consistency.

Once we receive your request we will contact you within 24-48 hours.