WasteWater Screens

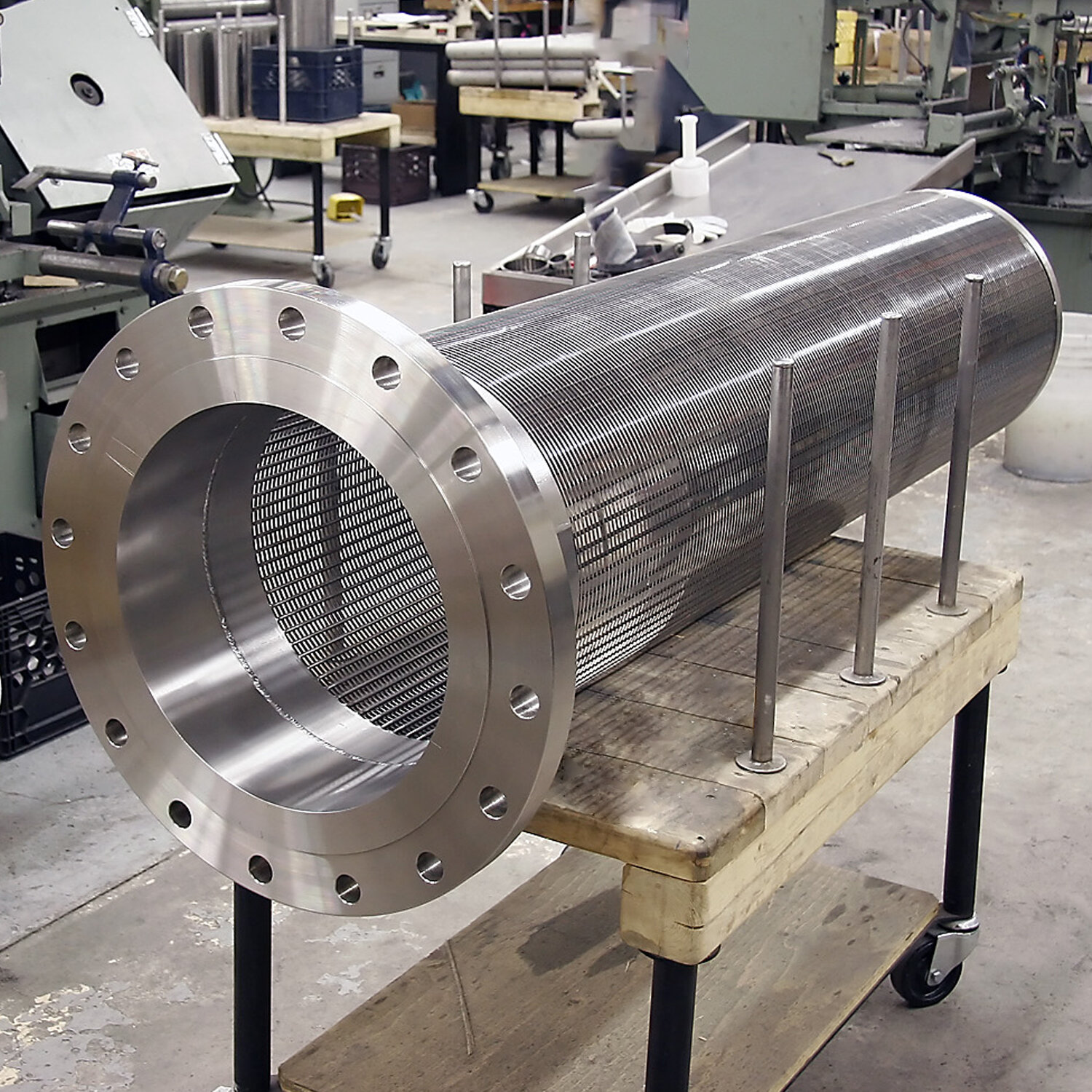

MBBR System Screens

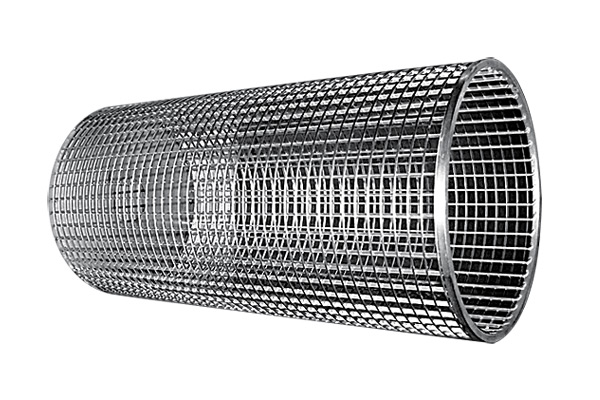

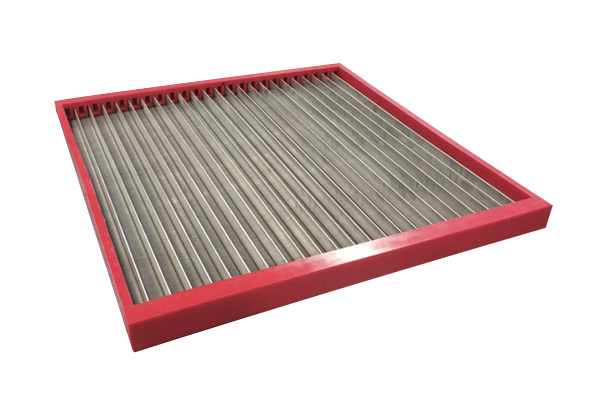

The wastewater treatment industry has a variety of applications which has benefited from the use of wedge wire screens. Available in flat, curved or cylindrical form, wedge wire is widely used in the reduction of solids in residential and industrial applications.

Specifications

Weld-RingxWeld-Ring

Weld-RingxCap

FlangexCap

FlangexWeld-Ring

Plain Squared Ends

Plain Ends (cut and shipped)

304/304L

316/ 316L

321

410S

Hastelloy C-276

Duplex

Super Duplex

Alloy B3

Monel 400

Alloy 20

Reducing the environmental pollution

A direct result in using wedge wire screens in the wastewater treatment applications has been a reduction of environmental pollution levels and lower operational costs over the years.

Commonly used as the first element of filtration during the operation at wastewater treatment plants, screening removes objects such as paper, plastics rags and metals that would damage and create clogging to the downstream equipment, piping, and appurtenances. Some of the newer wastewater plants will use multiple screens with coarse to fine slot types. We manufacture both types and to our customers’ drawings and specifications.

Fine screens

These are used to remove smaller particulate that create operation and maintenance problems. Fine screen openings are around the 0.06” to 0.25” range, and very fine screens can be fabricated with openings of 0.01” to 0.06”. They can reduce suspended solids to levels near those achieved by primary clarification.

Coarse screens

These are used by many OEMs in equipment designed to remove large solids and debris from wastewater flows. Slot sizes are typically larger than the 0.025” range.

Download 3D PDF:

Wastewater Screens

Requires Adobe Acrobat for 3D functionality. If screen is blank after clicking the download button, on the top right menu bar, hit “download”.

Benefits of our Wastewater Screens include:

Stronger and more durable due to resistance welding

Wide range of profile wire is available to suit most systems

High-precision slot sizes are available to meet your requirements

For surface filtration, the V-shaped surface wires allow for easy cleaning by mechanical scraping or backflushing or with the use of spray heads

Ease of replacement will reduce downtime

Engineered to your specifications

Robust for vertical wall applications

No lower sprockets, bushings or guides

Self-cleaning, when designed to the flow rate required

Typical Industries for use

Product Quote

Once we receive your request we will contact you within 48 hours.

Plain Screen

Wedge wire screens are manufactured by resistance welding V-shaped wire on support rods. The highest quality raw wire which is then made into a screen that is cut, shaped, fabricated and cleaned.

Can't find the screen you need?

We specialize in custom manufacturing. Our sales, engineering and production teams have the experience to manufacture what you need to the highest degree of excellence. Keeping all work in house allows us to offer accuracy and consistency.